Properties and Overview of Bronze Alloy PB102

Overview:

Bronze Alloys renowned for their rich history and exceptional properties, are vital to metallurgy and have uses spanning millennia. Typically composed of copper and tin, with possible additions of other elements like aluminum, nickel, or phosphorus, bronze is celebrated for its strength, durability, and resistance to corrosion. These characteristics make it an indispensable material in a wide range of applications.

Bronze Alloys renowned for their rich history and exceptional properties, are vital to metallurgy and have uses spanning millennia. Typically composed of copper and tin, with possible additions of other elements like aluminum, nickel, or phosphorus, bronze is celebrated for its strength, durability, and resistance to corrosion. These characteristics make it an indispensable material in a wide range of applications.

Production:

The production of bronze begins with the precise blending of copper and tin, melted together in controlled conditions. Additional elements are often introduced during smelting to enhance specific attributes, such as wear resistance or machinability. Once molten, the bronze is cast into molds to form ingots, which are processed into various shapes and forms. Advanced techniques like centrifugal and continuous casting often produce high-quality bronze components with uniform properties. The alloy's versatility allows it to be formed into sheets, rods, wires, and complex parts, catering to diverse industrial and artistic needs.

Applications:

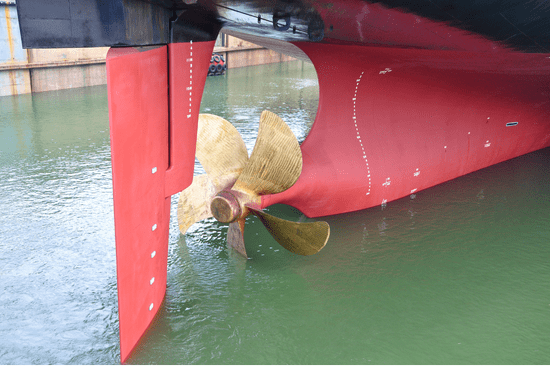

Bronze alloys find applications across numerous fields. In industrial settings, they are prized for their resistance to wear and corrosion, making them ideal for machinery components like bushings, bearings, and gears. Their non-sparking nature makes them essential in environments where flammable substances are present, such as in manufacturing tools for the petrochemical and mining industries. Bronze's excellent conductivity and durability have established its role in electrical systems used for connectors and terminals. Its resistance to seawater corrosion has made it a cornerstone of marine engineering, where it is employed in ship propellers, hull fittings, and underwater components. Beyond these functional uses, bronze's aesthetic qualities have made it a favored material for sculptures, monuments, and decorative elements, reflecting its enduring cultural significance.

The significance of bronze alloys extends beyond their technical properties to their role in sustainable manufacturing. Like brass, bronze is highly recyclable, and much of its production relies on recycled materials. This conserves resources and reduces the environmental impact of production processes, aligning with global sustainability goals.

Summary:

Bronze alloys embody a unique blend of historical legacy and modern utility. Their adaptability, strength, and corrosion resistance make them a material of choice across industries ranging from marine engineering to fine art. As innovation expands their applications and manufacturing processes, bronze remains a timeless alloy, bridging the gap between tradition and progress.

See a comprehensive list of electrical, mechanical, physical and thermal properties for Bronze Alloy PB102 below:

Electrical Properties of Bronze Alloy PB102

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

POLYMERS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

Mechanical Properties of Bronze Alloy PB102

| Mechanical Property (Units) | Value |

|---|---|

| Bronze Alloy PB102 Compressive Strength (MPa) | ~500 |

| Bronze Alloy PB102 Ductile to Brittle Transition Temperature (°C) | Unknown |

| Bronze Alloy PB102 Fatigue Limit (MPa) | ~100 to 120 |

| Bronze Alloy PB102 Fracture Toughness (MPa·√m) | ~60 to 80 |

| Bronze Alloy PB102 Hardness Brinell | 100 to 150 |

| Bronze Alloy PB102 Hardness Rockwell | 55 to 75 HRB |

| Bronze Alloy PB102 Hardness Vickers | 110 to 170 |

| Bronze Alloy PB102 Heat Deflection Temperature (°C) | N/A - Not a Polymer |

| Bronze Alloy PB102 Modulus of Elasticity / Young's Modulus (GPa) | 115 to 120 |

| Bronze Alloy PB102 Percent Elongation (%) | 10 to 20 |

| Bronze Alloy PB102 Poissons Ratio | 0.34 |

| Bronze Alloy PB102 Shear Modulus (GPa) | 44 |

| Bronze Alloy PB102 Shear Strength (MPa) | 180 to 250 |

| Bronze Alloy PB102 Ultimate Tensile Strength (MPa) | 450 to 550 |

| Bronze Alloy PB102 Yield Strength (MPa) | 220 to 300 |

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

POLYMERS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

Physical Properties of Bronze Alloy PB102

| Physical Property (Units) | Value |

|---|---|

| Bronze Alloy PB102 Boiling Point at Atmospheric Pressure (°C) | Unknown |

| Bronze Alloy PB102 Chemical Composition (Element %) | Cu 92%, Sn 6%, P 2% |

| Bronze Alloy PB102 Cost ($/kg) | 9 to 15 |

| Bronze Alloy PB102 Density at 'Standard Temperature and Pressure' (kg/m3) | 8800 |

| Bronze Alloy PB102 Glass Transition Temperature at Atmospheric Pressure (°C) | N/A - Not a Polymer |

| Bronze Alloy PB102 Melting Point at Atmospheric Pressure (°C) | 1010 to 1025 |

| Bronze Alloy PB102 Polymer Family | N/A - Not a Polymer |

| Bronze Alloy PB102 Refractive Index | Unknown |

| Bronze Alloy PB102 Specific Gravity | 8.8 |

| Bronze Alloy PB102 Viscosity at Melting Point (mPa·s) | 3 to 6 |

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

POLYMERS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

Thermal Properties of Bronze Alloy PB102

| Thermal Property (Units) | Value |

|---|---|

| Bronze Alloy PB102 Coefficient of Thermal Expansion (µm/m·K) | 18.0 |

| Bronze Alloy PB102 Emissivity Coefficient | 0.30 to 0.35 |

| Bronze Alloy PB102 Specific Heat Capacity (J/kg·K) | 380 |

| Bronze Alloy PB102 Thermal Conductivity (W/m.K) | 50 |

| Bronze Alloy PB102 Thermal Conductivity (BTU/h·ft·°F) | 28.91 |

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

POLYMERS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

ADDED TO MY FAVORITES!

ADDED TO MY FAVORITES! REMOVED FROM MY FAVORITES!

REMOVED FROM MY FAVORITES!