Properties and Overview of Engineering Steel EN16

Overview:

Engineering Steel is a versatile and high-performance material designed to meet the demanding requirements of industries that rely on strength, durability, and machinability. These steels are formulated explicitly with varying carbon, manganese, chromium, nickel compositions, and other elements to enhance mechanical properties like toughness, wear resistance, and fatigue strength. Engineering steel is widely used in applications where precision and reliability are critical, making it a cornerstone of modern manufacturing and construction.

Engineering Steel is a versatile and high-performance material designed to meet the demanding requirements of industries that rely on strength, durability, and machinability. These steels are formulated explicitly with varying carbon, manganese, chromium, nickel compositions, and other elements to enhance mechanical properties like toughness, wear resistance, and fatigue strength. Engineering steel is widely used in applications where precision and reliability are critical, making it a cornerstone of modern manufacturing and construction.

Production:

The production of engineering steel begins with carefully selecting raw materials, including iron ore and alloying elements, which are melted in a furnace to create a homogeneous mixture. Advanced techniques such as basic oxygen steelmaking (BOS) or electric arc furnaces (EAF) are employed to refine the steel and control its composition. Once the molten steel reaches the desired specification, it is cast into billets or slabs and undergoes various processes such as rolling, forging, and heat treatment. These steps are crucial for tailoring the microstructure and mechanical properties of the steel to specific applications. Heat treatments like quenching, tempering, or annealing often optimize strength, hardness, or ductility, ensuring the material performs under diverse operational conditions.

Applications:

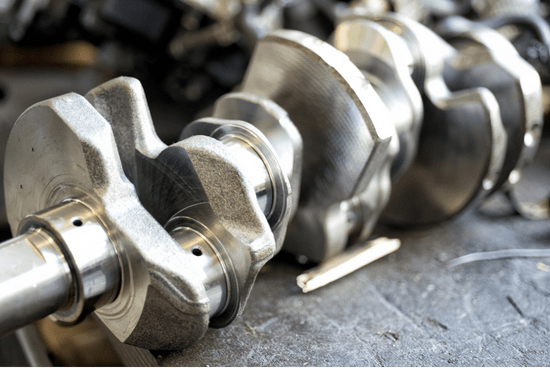

Engineering steel finds applications across a broad spectrum of industries. In the automotive sector, it is commonly used for components such as gears, axles, and crankshafts, where its strength and fatigue resistance are critical. Engineering steel is essential for structural components, fasteners, and reinforcements in construction, ensuring stability and longevity in buildings and infrastructure. The energy sector relies on high-performance steel for turbines, pipelines, and drilling equipment, which must withstand extreme temperatures, pressures, and corrosive environments. The material is used for machine tools, molds, and dies in manufacturing due to its wear resistance and machinability. Furthermore, engineering steel is a key material in producing railway tracks, aerospace components, and defense equipment, where reliability and safety are paramount.

Engineering steel's adaptability, coupled with advancements in alloy design and processing technologies, continues to expand its range of applications. Researchers are exploring innovative methods to enhance performance, such as developing ultra-high-strength steels and integrating sustainable production practices. Efforts to improve recyclability and reduce the environmental footprint of steel manufacturing are also gaining momentum, aligning with global goals for sustainability.

Summary:

Engineering Steel is a fundamental material that underpins countless aspects of modern industry and infrastructure. Its exceptional strength, durability, and versatility have made it indispensable in applications that demand reliability and performance. As advancements in material science and manufacturing continue to evolve, engineering steel will remain a critical enabler of progress, driving innovation and supporting the growth of industries worldwide.

See a comprehensive list of electrical, mechanical, physical and thermal properties for Engineering Steel EN16 below:

Electrical Properties of Engineering Steel EN16

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

POLYMERS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

Mechanical Properties of Engineering Steel EN16

| Mechanical Property (Units) | Value |

|---|---|

| Engineering Steel EN16 Compressive Strength (MPa) | ~950 |

| Engineering Steel EN16 Ductile to Brittle Transition Temperature (°C) | ~-50 |

| Engineering Steel EN16 Fatigue Limit (MPa) | 250 to 280 |

| Engineering Steel EN16 Fracture Toughness (MPa·√m) | ~75 |

| Engineering Steel EN16 Hardness Brinell | 190 to 260 |

| Engineering Steel EN16 Hardness Rockwell | 20 to 30 HRC |

| Engineering Steel EN16 Hardness Vickers | 200 to 270 |

| Engineering Steel EN16 Heat Deflection Temperature (°C) | N/A - Not a Polymer |

| Engineering Steel EN16 Modulus of Elasticity / Young's Modulus (GPa) | 205 |

| Engineering Steel EN16 Percent Elongation (%) | 13 to 16 |

| Engineering Steel EN16 Poissons Ratio | 0.29 |

| Engineering Steel EN16 Shear Modulus (GPa) | 80 |

| Engineering Steel EN16 Shear Strength (MPa) | 420 to 470 |

| Engineering Steel EN16 Ultimate Tensile Strength (MPa) | 700 to 900 |

| Engineering Steel EN16 Yield Strength (MPa) | 450 to 520 |

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

POLYMERS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

Physical Properties of Engineering Steel EN16

| Physical Property (Units) | Value |

|---|---|

| Engineering Steel EN16 Boiling Point at Atmospheric Pressure (°C) | Unknown |

| Engineering Steel EN16 Chemical Composition (Element %) | C 0.36-0.44%, Mn 0.45-0.70%, Si 0.10-0.40%, Cr 0.90-1.20%, Mo 0.15-0.30%, Fe balance |

| Engineering Steel EN16 Cost ($/kg) | 2 to 4 |

| Engineering Steel EN16 Density at 'Standard Temperature and Pressure' (kg/m3) | 7850 |

| Engineering Steel EN16 Glass Transition Temperature at Atmospheric Pressure (°C) | N/A - Not a Polymer |

| Engineering Steel EN16 Melting Point at Atmospheric Pressure (°C) | 1425 to 1460 |

| Engineering Steel EN16 Polymer Family | N/A - Not a Polymer |

| Engineering Steel EN16 Refractive Index | Unknown |

| Engineering Steel EN16 Specific Gravity | 7.85 |

| Engineering Steel EN16 Viscosity at Melting Point (mPa·s) | 4 to 7 |

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

POLYMERS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

Thermal Properties of Engineering Steel EN16

| Thermal Property (Units) | Value |

|---|---|

| Engineering Steel EN16 Coefficient of Thermal Expansion (µm/m·K) | 11.5 to 12.5 |

| Engineering Steel EN16 Emissivity Coefficient | 0.35 to 0.40 |

| Engineering Steel EN16 Specific Heat Capacity (J/kg·K) | 475 |

| Engineering Steel EN16 Thermal Conductivity (W/m.K) | 42 |

| Engineering Steel EN16 Thermal Conductivity (BTU/h·ft·°F) | 24.28 |

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

POLYMERS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

ADDED TO MY FAVORITES!

ADDED TO MY FAVORITES! REMOVED FROM MY FAVORITES!

REMOVED FROM MY FAVORITES!