Properties and Overview of Magnesium Alloy AZ31

Overview:

Magnesium Alloys are among the lightest structural materials available, combining a low density with excellent strength and versatility. These alloys, made primarily from magnesium combined with elements such as aluminum, zinc, manganese, and rare earth metals, are widely used in industries that demand lightweight solutions without compromising performance. Their unique properties, including good corrosion resistance and exceptional machinability, make them increasingly valuable in modern engineering and manufacturing.

Magnesium Alloys are among the lightest structural materials available, combining a low density with excellent strength and versatility. These alloys, made primarily from magnesium combined with elements such as aluminum, zinc, manganese, and rare earth metals, are widely used in industries that demand lightweight solutions without compromising performance. Their unique properties, including good corrosion resistance and exceptional machinability, make them increasingly valuable in modern engineering and manufacturing.

Production:

The production of magnesium alloys begins with the extraction of magnesium, typically from sources like seawater or mineral deposits such as magnesite and dolomite. Once extracted, magnesium is combined with other alloying elements in a controlled environment to create specific compositions that enhance desired properties, such as strength or corrosion resistance. The molten alloy is then cast into billets, ingots, or near-net shapes using die casting, sand casting, or permanent mold casting. Advanced techniques like thixomolding and semi-solid casting are also employed to produce components with superior surface quality and mechanical properties. Post-casting processes, including machining, heat treatment, and surface finishing, refine the material further to meet application-specific requirements.

Applications:

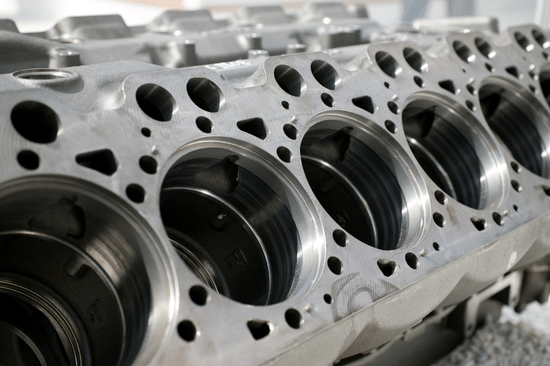

Magnesium alloys are used across a diverse array of industries. In the automotive and aerospace sectors, their lightweight nature is crucial in reducing vehicle weight, improving fuel efficiency, and enhancing performance. Engine blocks, transmission cases, and aircraft structural parts frequently utilize magnesium alloys. Magnesium is a popular choice for housing and enclosures in electronics, as it provides robust protection while minimizing weight. Its thermal and electromagnetic shielding properties further enhance its appeal in this sector. Magnesium alloys are gaining attention in the biomedical field for their potential as biodegradable implants, particularly in bone repair applications, where they naturally dissolve after fulfilling their function. Additionally, they are used in sporting goods, portable tools, and even defense equipment, where weight reduction is a critical consideration.

Magnesium alloys also contribute to sustainability due to their recyclability and the relatively low energy required for their extraction and production compared to other metals. However, challenges like limited corrosion resistance in specific environments and the high cost of some alloying elements have driven ongoing research and innovation. Advances in protective coatings, alloy formulations, and manufacturing technologies are continually enhancing the performance and cost-effectiveness of magnesium alloys, broadening their application scope.

Summary:

Magnesium alloys represent a remarkable intersection of lightweight engineering and modern manufacturing demands. Their unique properties have made them indispensable in the automotive and biomedical industries. With continued advancements in processing techniques and material science, magnesium alloys are poised to play an even more significant role in addressing the challenges of efficiency, sustainability, and innovation in the years to come.

See a comprehensive list of electrical, mechanical, physical and thermal properties for Magnesium Alloy AZ31 below:

Electrical Properties of Magnesium Alloy AZ31

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

POLYMERS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

Mechanical Properties of Magnesium Alloy AZ31

| Mechanical Property (Units) | Value |

|---|---|

| Magnesium Alloy AZ31 Compressive Strength (MPa) | ~300 |

| Magnesium Alloy AZ31 Ductile to Brittle Transition Temperature (°C) | ~-100 |

| Magnesium Alloy AZ31 Fatigue Limit (MPa) | ~90 to 110 |

| Magnesium Alloy AZ31 Fracture Toughness (MPa·√m) | ~20 to 30 |

| Magnesium Alloy AZ31 Hardness Brinell | 45 to 60 |

| Magnesium Alloy AZ31 Hardness Rockwell | 45 to 50 HRB |

| Magnesium Alloy AZ31 Hardness Vickers | 55 to 70 |

| Magnesium Alloy AZ31 Heat Deflection Temperature (°C) | N/A - Not a Polymer |

| Magnesium Alloy AZ31 Modulus of Elasticity / Young's Modulus (GPa) | 45 |

| Magnesium Alloy AZ31 Percent Elongation (%) | 15 to 20 |

| Magnesium Alloy AZ31 Poissons Ratio | 0.35 |

| Magnesium Alloy AZ31 Shear Modulus (GPa) | 17 |

| Magnesium Alloy AZ31 Shear Strength (MPa) | 150 |

| Magnesium Alloy AZ31 Ultimate Tensile Strength (MPa) | 250 to 280 |

| Magnesium Alloy AZ31 Yield Strength (MPa) | 140 to 180 |

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

POLYMERS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

Physical Properties of Magnesium Alloy AZ31

| Physical Property (Units) | Value |

|---|---|

| Magnesium Alloy AZ31 Boiling Point at Atmospheric Pressure (°C) | Unknown |

| Magnesium Alloy AZ31 Chemical Composition (Element %) | Mg balance, Al 2.5-3.5%, Zn 0.6-1.4%, Mn ≥ 0.20% |

| Magnesium Alloy AZ31 Cost ($/kg) | 6 to 9 |

| Magnesium Alloy AZ31 Density at 'Standard Temperature and Pressure' (kg/m3) | 1780 |

| Magnesium Alloy AZ31 Glass Transition Temperature at Atmospheric Pressure (°C) | N/A - Not a Polymer |

| Magnesium Alloy AZ31 Melting Point at Atmospheric Pressure (°C) | 620 to 650 |

| Magnesium Alloy AZ31 Polymer Family | N/A - Not a Polymer |

| Magnesium Alloy AZ31 Refractive Index | Unknown |

| Magnesium Alloy AZ31 Specific Gravity | 1.78 |

| Magnesium Alloy AZ31 Viscosity at Melting Point (mPa·s) | 1.0 to 1.5 |

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

POLYMERS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

Thermal Properties of Magnesium Alloy AZ31

| Thermal Property (Units) | Value |

|---|---|

| Magnesium Alloy AZ31 Coefficient of Thermal Expansion (µm/m·K) | 26.8 |

| Magnesium Alloy AZ31 Emissivity Coefficient | 0.40 to 0.45 |

| Magnesium Alloy AZ31 Specific Heat Capacity (J/kg·K) | 1020 |

| Magnesium Alloy AZ31 Thermal Conductivity (W/m.K) | 96 |

| Magnesium Alloy AZ31 Thermal Conductivity (BTU/h·ft·°F) | 55.50 |

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

POLYMERS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

ADDED TO MY FAVORITES!

ADDED TO MY FAVORITES! REMOVED FROM MY FAVORITES!

REMOVED FROM MY FAVORITES!