Properties and Overview of Nickel Alloy Inconel 625

Overview:

Nickel Alloy are celebrated for their exceptional strength, corrosion resistance, and thermal stability, making them indispensable in demanding environments. Composed primarily of nickel with varying amounts of elements such as chromium, iron, cobalt, and molybdenum, these alloys are engineered to perform under extreme conditions, including high temperatures and corrosive environments. Their versatility and reliability have made them vital across aerospace, energy, and chemical processing industries.

Nickel Alloy are celebrated for their exceptional strength, corrosion resistance, and thermal stability, making them indispensable in demanding environments. Composed primarily of nickel with varying amounts of elements such as chromium, iron, cobalt, and molybdenum, these alloys are engineered to perform under extreme conditions, including high temperatures and corrosive environments. Their versatility and reliability have made them vital across aerospace, energy, and chemical processing industries.

Production:

The production of nickel alloys begins with the extraction and refining of nickel from ore, followed by blending it with other alloying elements to achieve the desired properties. Advanced melting processes, including vacuum induction melting and electro-slag remelting, are employed to ensure high purity and uniformity in the alloy's composition. The molten material is then cast into ingots or billets, which undergo secondary processes like forging, rolling, or extrusion to create sheets, rods, or tubes. Heat treatments such as annealing or solution treatment refine the microstructure, enhancing mechanical properties and resistance to environmental stressors.

Applications:

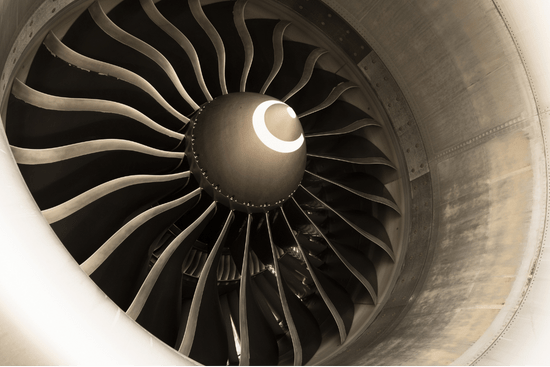

Nickel alloys are widely used in applications that demand durability and performance in harsh conditions. In the aerospace industry, they are critical for components like turbine blades, engine casings, and exhaust systems, where their ability to withstand extreme heat and stress ensures safety and efficiency. In the energy sector, nickel alloys are essential for gas turbines, nuclear reactors, and renewable energy systems, where they resist oxidation and maintain stability under fluctuating temperatures. The chemical processing industry relies on these alloys for equipment such as heat exchangers, reactors, and piping systems that handle corrosive substances. Additionally, nickel alloys are used in medical devices, electronics, and marine engineering, where their biocompatibility, conductivity, and resistance to seawater corrosion are highly valued.

As industries evolve, developing advanced nickel alloys continues to address emerging challenges. Innovations in alloy formulation enhance properties like fatigue resistance, machinability, and performance in extreme environments, broadening their application scope. Moreover, nickel alloys are pivotal in sustainability initiatives, particularly in energy-efficient systems and renewable technologies. Their recyclability further contributes to their environmental appeal, as reclaimed nickel alloys can be reused without significantly losing quality.

Summary:

Nickel alloys are a cornerstone of modern engineering, offering unmatched performance in some of the world's most challenging environments. Their unique combination of strength, corrosion resistance, and thermal stability has established them as essential materials across various industries. As advancements in material science and sustainable practices continue, nickel alloys will remain a critical driver of innovation, enabling progress in traditional and cutting-edge applications.

See a comprehensive list of electrical, mechanical, physical and thermal properties for Nickel Alloy Inconel 625 below:

Electrical Properties of Nickel Alloy Inconel 625

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

POLYMERS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

Mechanical Properties of Nickel Alloy Inconel 625

| Mechanical Property (Units) | Value |

|---|---|

| Nickel Alloy Inconel 625 Compressive Strength (MPa) | ~1000 |

| Nickel Alloy Inconel 625 Ductile to Brittle Transition Temperature (°C) | -196 to -150 |

| Nickel Alloy Inconel 625 Fatigue Limit (MPa) | ~280 to 400 |

| Nickel Alloy Inconel 625 Fracture Toughness (MPa·√m) | ~210 |

| Nickel Alloy Inconel 625 Hardness Brinell | 170 to 240 |

| Nickel Alloy Inconel 625 Hardness Rockwell | 95 HRB to 35 HRC |

| Nickel Alloy Inconel 625 Hardness Vickers | 200 to 245 |

| Nickel Alloy Inconel 625 Heat Deflection Temperature (°C) | N/A - Not a Polymer |

| Nickel Alloy Inconel 625 Modulus of Elasticity / Young's Modulus (GPa) | 205 to 214 |

| Nickel Alloy Inconel 625 Percent Elongation (%) | 30 to 40 |

| Nickel Alloy Inconel 625 Poissons Ratio | 0.31 |

| Nickel Alloy Inconel 625 Shear Modulus (GPa) | 82 |

| Nickel Alloy Inconel 625 Shear Strength (MPa) | 570 |

| Nickel Alloy Inconel 625 Ultimate Tensile Strength (MPa) | 830 to 1030 |

| Nickel Alloy Inconel 625 Yield Strength (MPa) | 414 to 520 |

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

POLYMERS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

Physical Properties of Nickel Alloy Inconel 625

| Physical Property (Units) | Value |

|---|---|

| Nickel Alloy Inconel 625 Boiling Point at Atmospheric Pressure (°C) | Unknown |

| Nickel Alloy Inconel 625 Chemical Composition (Element %) | Ni 58.0-63.0%, Cr 20.0-23.0%, Mo 8.0-10.0%, Fe 5.0%, Nb 3.15-4.15%, C ≤ 0.10%, Mn ≤ 0.50%, Si ≤ 0.50% |

| Nickel Alloy Inconel 625 Cost ($/kg) | 20 to 35 |

| Nickel Alloy Inconel 625 Density at 'Standard Temperature and Pressure' (kg/m3) | 8440 |

| Nickel Alloy Inconel 625 Glass Transition Temperature at Atmospheric Pressure (°C) | N/A - Not a Polymer |

| Nickel Alloy Inconel 625 Melting Point at Atmospheric Pressure (°C) | 1290 to 1350 |

| Nickel Alloy Inconel 625 Polymer Family | N/A - Not a Polymer |

| Nickel Alloy Inconel 625 Refractive Index | Unknown |

| Nickel Alloy Inconel 625 Specific Gravity | 8.44 |

| Nickel Alloy Inconel 625 Viscosity at Melting Point (mPa·s) | 4 to 7 |

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

POLYMERS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

Thermal Properties of Nickel Alloy Inconel 625

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

POLYMERS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

ADDED TO MY FAVORITES!

ADDED TO MY FAVORITES! REMOVED FROM MY FAVORITES!

REMOVED FROM MY FAVORITES!