Properties and Overview of Tool Steel BD2

Overview:

Tool Steel is a specialized category of steel designed to manufacture tools, dies, and machine parts that require exceptional hardness, wear resistance, and durability. Composed of varying amounts of carbon and alloying elements such as tungsten, molybdenum, chromium, vanadium, and cobalt, tool steel is engineered to maintain strength and performance even under extreme operating conditions like high temperatures and heavy loads. Its unique properties make it essential in industries that demand precision and reliability.

Tool Steel is a specialized category of steel designed to manufacture tools, dies, and machine parts that require exceptional hardness, wear resistance, and durability. Composed of varying amounts of carbon and alloying elements such as tungsten, molybdenum, chromium, vanadium, and cobalt, tool steel is engineered to maintain strength and performance even under extreme operating conditions like high temperatures and heavy loads. Its unique properties make it essential in industries that demand precision and reliability.

Production:

Tool steel production begins with carefully selecting and melting raw materials in advanced furnaces, such as electric arc furnaces or induction furnaces. The molten steel is refined to achieve the desired chemical composition, and alloying elements are added to enhance properties like hardness or thermal resistance. After casting, the steel is subjected to secondary processing techniques such as rolling, forging, or extrusion to shape it into billets, bars, or sheets. Heat treatment processes, including hardening, tempering, and annealing, are critical to optimizing the microstructure of tool steel, ensuring it can withstand the rigors of high-stress applications. Precision machining and surface treatments may be applied to tailor the material to its intended use.

Applications:

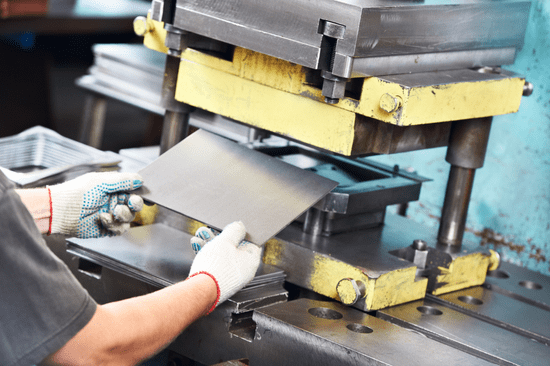

Tool steel is indispensable in applications that require exceptional durability and precision. It is widely used in manufacturing cutting tools such as drills, saws, and milling cutters, which must retain sharp edges and resist wear during prolonged use. In die-making, tool steel is the material of choice for forging dies, stamping dies, and extrusion tools, as it can endure the high pressures and temperatures involved in shaping other metals. The automotive and aerospace industries rely on tool steel for components like molds and dies used to produce parts with complex geometries. Additionally, it plays a critical role in making plastic molds, shear blades, punches, and industrial knives, where its toughness and dimensional stability are paramount. Tool steel's high thermal resistance is also suitable for components in high-temperature environments, such as turbine blades and engine parts.

Advancements in tool steel technology continue to expand its capabilities and applications. Innovative alloy formulations and heat treatment techniques are being developed to enhance properties like wear resistance, toughness, and machinability. Efforts to improve the sustainability of tool steel production, such as increasing the use of recycled materials and adopting energy-efficient manufacturing processes, are also gaining importance in the industry.

Summary:

Tool steel is a vital material that supports precision manufacturing, heavy industry, and high-performance engineering. Its exceptional hardness, wear resistance, and ability to maintain performance under extreme conditions have made it indispensable across various applications. As material science advances and industries demand greater efficiency and sustainability, tool steel will remain a cornerstone of innovation, enabling the production of tools and components that drive progress in countless fields.

See a comprehensive list of electrical, mechanical, physical and thermal properties for Tool Steel BD2 below:

Electrical Properties of Tool Steel BD2

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

POLYMERS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

Mechanical Properties of Tool Steel BD2

| Mechanical Property (Units) | Value |

|---|---|

| Tool Steel BD2 Compressive Strength (MPa) | ~1000 |

| Tool Steel BD2 Ductile to Brittle Transition Temperature (°C) | ~-50 |

| Tool Steel BD2 Fatigue Limit (MPa) | ~350 to 450 |

| Tool Steel BD2 Fracture Toughness (MPa·√m) | ~50 to 80 |

| Tool Steel BD2 Hardness Brinell | 300 to 450 |

| Tool Steel BD2 Hardness Rockwell | 30 to 45 HRC |

| Tool Steel BD2 Hardness Vickers | 320 to 500 |

| Tool Steel BD2 Heat Deflection Temperature (°C) | N/A - Not a Polymer |

| Tool Steel BD2 Modulus of Elasticity / Young's Modulus (GPa) | 200 to 210 |

| Tool Steel BD2 Percent Elongation (%) | ~10 |

| Tool Steel BD2 Poissons Ratio | 0.28 |

| Tool Steel BD2 Shear Modulus (GPa) | 80 to 85 |

| Tool Steel BD2 Shear Strength (MPa) | 600 to 750 |

| Tool Steel BD2 Ultimate Tensile Strength (MPa) | 700 to 850 |

| Tool Steel BD2 Yield Strength (MPa) | 550 to 650 |

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

POLYMERS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

Physical Properties of Tool Steel BD2

| Physical Property (Units) | Value |

|---|---|

| Tool Steel BD2 Boiling Point at Atmospheric Pressure (°C) | Unknown |

| Tool Steel BD2 Chemical Composition (Element %) | C 1.5-2.0%, Mn 0.20-0.45%, Cr 11.0-13.0%, Mo ≤ 0.50%, Fe balance |

| Tool Steel BD2 Cost ($/kg) | 8 to 12 |

| Tool Steel BD2 Density at 'Standard Temperature and Pressure' (kg/m3) | 7700 |

| Tool Steel BD2 Glass Transition Temperature at Atmospheric Pressure (°C) | N/A - Not a Polymer |

| Tool Steel BD2 Melting Point at Atmospheric Pressure (°C) | 1420 to 1460 |

| Tool Steel BD2 Polymer Family | N/A - Not a Polymer |

| Tool Steel BD2 Refractive Index | Unknown |

| Tool Steel BD2 Specific Gravity | 7.7 |

| Tool Steel BD2 Viscosity at Melting Point (mPa·s) | 5 to 8 |

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

POLYMERS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

Thermal Properties of Tool Steel BD2

| Thermal Property (Units) | Value |

|---|---|

| Tool Steel BD2 Coefficient of Thermal Expansion (µm/m·K) | 10.0 to 12.0 |

| Tool Steel BD2 Emissivity Coefficient | 0.35 to 0.40 |

| Tool Steel BD2 Specific Heat Capacity (J/kg·K) | 460 |

| Tool Steel BD2 Thermal Conductivity (W/m.K) | 21 |

| Tool Steel BD2 Thermal Conductivity (BTU/h·ft·°F) | 12.14 |

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

POLYMERS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

ADDED TO MY FAVORITES!

ADDED TO MY FAVORITES! REMOVED FROM MY FAVORITES!

REMOVED FROM MY FAVORITES!