Properties and Overview of PDMS (Polydimethylsiloxane)

Overview:

PDMS (Polydimethylsiloxane) is a versatile silicone-based polymer renowned for its flexibility, biocompatibility, and chemical stability. As one of the most widely used silicones, PDMS is a critical material in industries ranging from healthcare and electronics to construction and consumer goods. Its unique properties, including thermal stability, low surface energy, and resistance to water and chemicals, make it an indispensable material for a broad range of applications.

PDMS (Polydimethylsiloxane) is a versatile silicone-based polymer renowned for its flexibility, biocompatibility, and chemical stability. As one of the most widely used silicones, PDMS is a critical material in industries ranging from healthcare and electronics to construction and consumer goods. Its unique properties, including thermal stability, low surface energy, and resistance to water and chemicals, make it an indispensable material for a broad range of applications.

Production:

PDMS is synthesized by polymerizing dimethylsiloxane monomers in the presence of a catalyst. The polymer's structure consists of a silicon-oxygen backbone with organic methyl groups attached, giving it its characteristic flexibility and inertness. PDMS can be produced in various viscosities, from low-viscosity liquids to high-viscosity gums and elastomers, allowing customization to suit specific needs. It is often crosslinked or cured to create solid, durable materials with enhanced mechanical properties, such as silicone rubber or resins.

Applications:

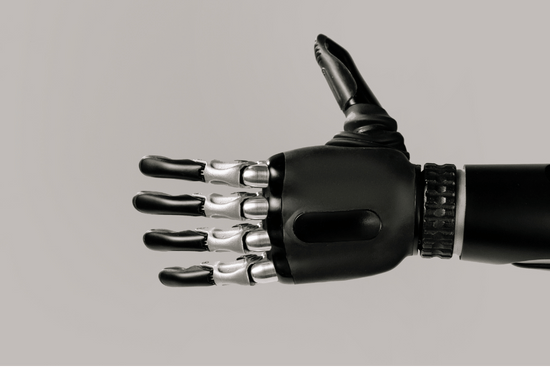

Applications of PDMS are extensive and diverse due to its remarkable properties. PDMS is used for implants, prosthetics, and medical tubing in the medical field due to its biocompatibility and resistance to sterilization processes. It plays a crucial role in microfluidics, where its optical transparency and ease of molding allow for the creation of intricate lab-on-chip devices. In electronics, PDMS serves as an encapsulant and protective coating for sensitive components, offering insulation and protection from environmental factors. The construction industry relies on PDMS for sealants and adhesives that withstand temperature fluctuations and weathering. Additionally, it is used in personal care products, such as shampoos and lotions, due to its smooth texture and water-repellent properties. In industrial applications, PDMS is a key ingredient in lubricants, antifoaming agents, and release coatings.

Summary:

PDMS is a highly adaptable polymer with properties that make it a cornerstone material in modern technology and industry. Its flexibility, stability, and biocompatibility have established it as a reliable solution for applications ranging from medical devices to advanced electronics. As innovation continues to expand the possibilities of PDMS, it remains a vital material driving advancements in diverse fields.

See a comprehensive list of electrical, mechanical, physical and thermal properties for PDMS (Polydimethylsiloxane) below:

Electrical Properties of PDMS (Polydimethylsiloxane)

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

ALLOYS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

Mechanical Properties of PDMS (Polydimethylsiloxane)

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

ALLOYS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

Physical Properties of PDMS (Polydimethylsiloxane)

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

ALLOYS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

Thermal Properties of PDMS (Polydimethylsiloxane)

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

ALLOYS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

ADDED TO MY FAVORITES!

ADDED TO MY FAVORITES! REMOVED FROM MY FAVORITES!

REMOVED FROM MY FAVORITES!