Properties and Overview of PPO (Polyphenyleneoxide)

Overview:

PPO (Polyphenyleneoxide) is a high-performance thermoplastic polymer known for its exceptional thermal stability, dimensional stability, and resistance to moisture and chemicals. As a lightweight material with excellent electrical insulating properties, PPO is widely used in industries requiring materials that can maintain performance under demanding conditions. Its versatility and durability make it a key material in the automotive, electrical, and consumer goods sectors.

PPO (Polyphenyleneoxide) is a high-performance thermoplastic polymer known for its exceptional thermal stability, dimensional stability, and resistance to moisture and chemicals. As a lightweight material with excellent electrical insulating properties, PPO is widely used in industries requiring materials that can maintain performance under demanding conditions. Its versatility and durability make it a key material in the automotive, electrical, and consumer goods sectors.

Production:

The production of PPO involves the oxidative polymerization of phenol derivatives, typically catalyzed by a copper-based system. This process creates a polymer with a highly stable aromatic backbone, contributing to its thermal resistance and mechanical strength. PPO is often blended with other materials, such as polystyrene (PS), to enhance its processability and broaden its application range. These blends, such as Noryl, combine the best properties of PPO with improved ease of manufacturing, allowing for cost-effective production of high-performance components.

Applications:

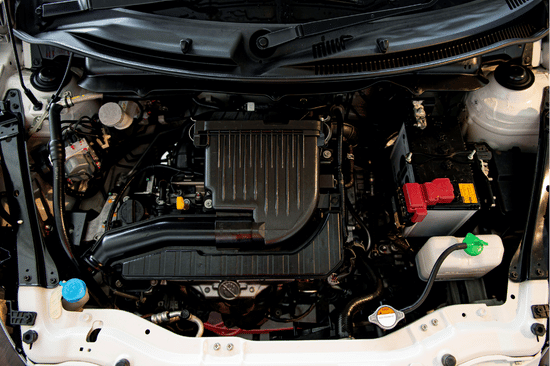

PPO's applications are extensive due to its unique combination of properties. In the automotive industry, PPO is used for under-the-hood components, fuel system parts, and electrical connectors, where its resistance to heat, chemicals, and mechanical stress ensures reliability and safety. In the electrical and electronics sectors, PPO serves as a material for circuit boards, insulators, and housings, benefiting from its excellent dielectric properties and resistance to moisture. The material is also employed in consumer goods, such as kitchen appliances and water filtration systems, where its toughness and resistance to hot water are critical. Additionally, PPO is found in industrial applications, including pumps, valves, and structural parts, where its strength and stability make it a preferred choice.

Summary:

Polyphenyleneoxide is a versatile and high-performing thermoplastic that combines durability, thermal stability, and electrical insulation properties. Its adaptability and ability to meet stringent industry requirements make it a reliable material for applications ranging from automotive to electronics and consumer goods. As innovation expands the possibilities for advanced materials, PPO remains vital in modern engineering and manufacturing, ensuring performance and reliability in various applications. Its enduring relevance highlights its importance in driving progress across industries.

See a comprehensive list of electrical, mechanical, physical and thermal properties for PPO (Polyphenyleneoxide) below:

Electrical Properties of PPO (Polyphenyleneoxide)

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

ALLOYS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

Mechanical Properties of PPO (Polyphenyleneoxide)

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

ALLOYS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

Physical Properties of PPO (Polyphenyleneoxide)

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

ALLOYS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

Thermal Properties of PPO (Polyphenyleneoxide)

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

ALLOYS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

ADDED TO MY FAVORITES!

ADDED TO MY FAVORITES! REMOVED FROM MY FAVORITES!

REMOVED FROM MY FAVORITES!