Properties and Overview of PPSu (Polyphenylsulphone)

Overview:

PPSu (Polyphenylsulphone) is a high-performance thermoplastic polymer recognized for its outstanding thermal stability, chemical resistance, and impact strength. As a member of the polysulfone family, PPSU stands out for its ability to maintain mechanical and structural integrity under extreme conditions, including high temperatures and exposure to harsh chemicals. These properties make PPSU a preferred material in healthcare, aerospace, automotive, and industrial manufacturing industries.

PPSu (Polyphenylsulphone) is a high-performance thermoplastic polymer recognized for its outstanding thermal stability, chemical resistance, and impact strength. As a member of the polysulfone family, PPSU stands out for its ability to maintain mechanical and structural integrity under extreme conditions, including high temperatures and exposure to harsh chemicals. These properties make PPSU a preferred material in healthcare, aerospace, automotive, and industrial manufacturing industries.

Production:

The production of PPSU involves the polymerization of diphenyl sulfone and aromatic bisphenol monomers, creating a rigid molecular structure with high thermal and chemical stability. PPSU's amorphous nature gives it exceptional toughness and transparency, distinguishing it from other high-performance plastics. The polymer can be processed through conventional methods such as injection molding, extrusion, and thermoforming, allowing for the creation of complex and precise components. PPSU is often selected for applications requiring superior durability and resistance to hydrolysis and sterilization.

Applications:

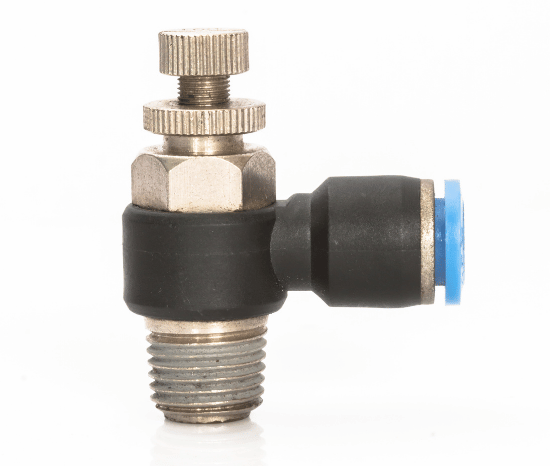

PPSU's applications are extensive due to its unique properties. In the healthcare sector, PPSU is widely used for medical devices, sterilization trays, and surgical instruments, where its resistance to repeated autoclaving and biocompatibility are critical. The aerospace industry employs PPSU for interior components, such as seat frames and paneling, benefiting from its flame resistance, lightweight nature, and durability. In the automotive sector, PPSU is used for fuel system components, fittings, and lighting housings, where its ability to withstand high temperatures and chemicals ensures reliability. Additionally, PPSU is utilized in plumbing systems for fittings, manifolds, and water filtration components, as it offers excellent resistance to hot water and corrosion. Its use extends to industrial machinery and electronics, where it is a robust material for insulating and structural parts.

Summary:

Polyphenylsulfone is a versatile and durable polymer that combines exceptional thermal stability, chemical resistance, and mechanical strength. Its adaptability to extreme conditions makes it a vital material for advanced applications in healthcare, aerospace, automotive, and beyond. As industries demand high-performance materials prioritizing reliability and longevity, PPSU remains a critical solution for meeting modern engineering and manufacturing challenges. Its proven track record and potential for innovation ensure its ongoing importance in shaping the future of material science and industrial design.

See a comprehensive list of electrical, mechanical, physical and thermal properties for PPSu (Polyphenylsulphone) below:

Electrical Properties of PPSu (Polyphenylsulphone)

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

ALLOYS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

Mechanical Properties of PPSu (Polyphenylsulphone)

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

ALLOYS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

Physical Properties of PPSu (Polyphenylsulphone)

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

ALLOYS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

Thermal Properties of PPSu (Polyphenylsulphone)

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

ALLOYS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

ADDED TO MY FAVORITES!

ADDED TO MY FAVORITES! REMOVED FROM MY FAVORITES!

REMOVED FROM MY FAVORITES!